When it comes to preparing milk replacers, understanding, and maintaining the right temperature is crucial for ensuring proper nutrient breakdown and calf digestion. Let’s dive into the key aspects of temperature control in the milk mixing and feeding process.

Mixing Temperature: Unlocking Nutrient Potential

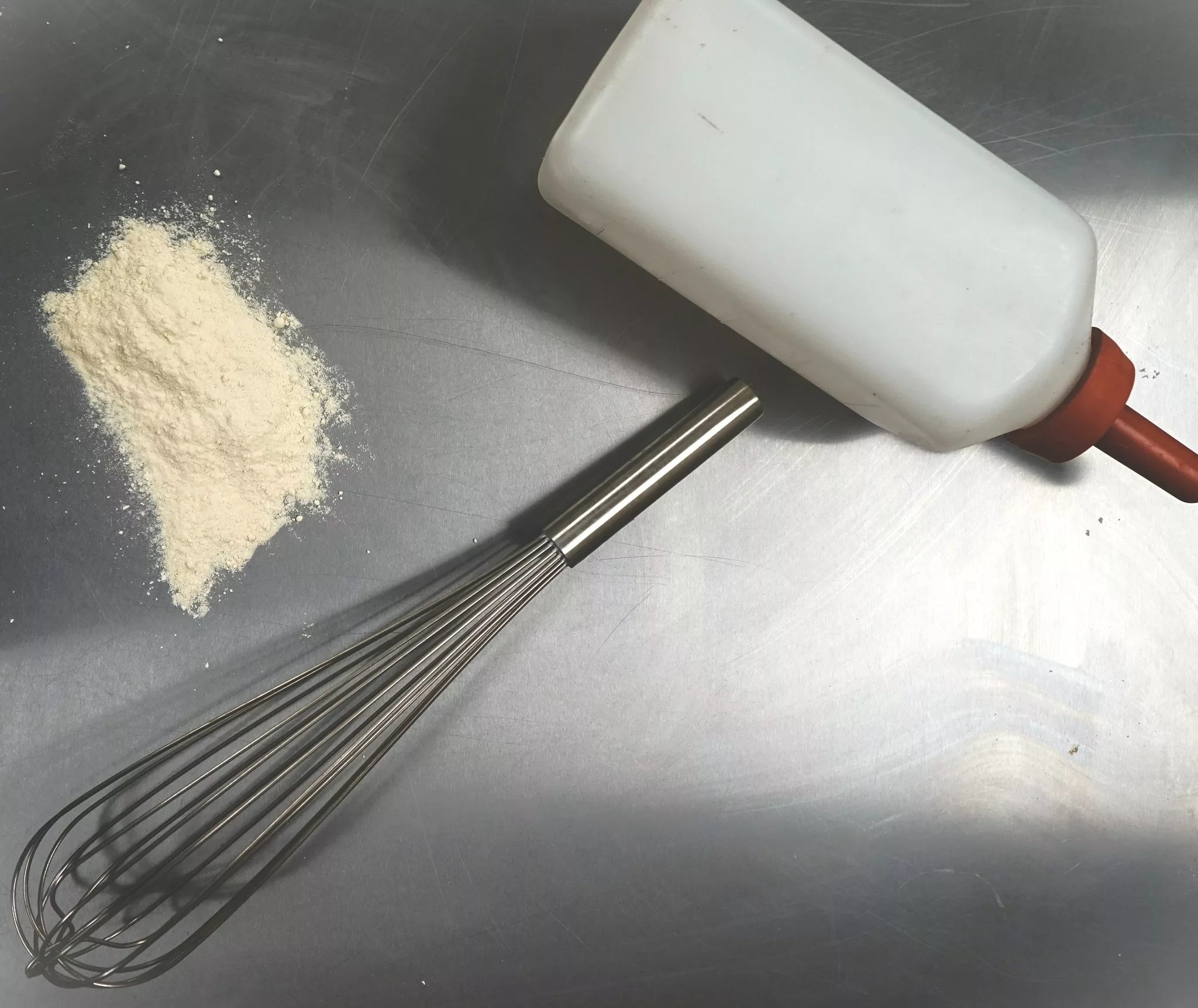

Milk replacers primarily consist of water-soluble ingredients, intended to form a consistent solution when mixed with water. Achieving the right temperature is vital to unlock the nutrients in the powder for optimal digestion by the calf. For Esmilco milk replacers, the recommended water temperature for mixing falls within the range of 120°F to 140°F. This temperature range promotes the effective breakdown of the powder’s fat content. It’s important to note that milk replacer mainly comprises protein, lactose, and fat components. During production, proteins adhere to fats, creating a coating around fat droplets. This bond prevents fat droplets from combining and making a stable product. To facilitate the interaction between fat and water, the fat needs to melt into the solution, which is why a hot enough temperature is so important.

Fats found in milk replacers usually emulsify into solution around 110°F. Once this occurs, fat and protein stay suspended in the water causing a uniform solution to occur.

One aspect that can cause an issue is mixing with too cold of a water temperature. The most common issue we see here, is the fat particle does not melt due to the water temperature being below the fat melting point. The melting point of our combination of fats, on average, is 110°F. If the water temperature is below that, we are not creating a uniform solution. Essentially the fat is still sitting as a solid inside the liquid. When this issue arises, or when milk replacer is overmixed, you will likely see a greasy residue on equipment due to that fat not going into solution as intended. You might also see some clumping of the milk replacer due to too low of temperatures.

Issues can also arise if the milk replacer is mixed at too high of a temperature as well. Mixing at temperatures above 140°F risks denaturing the protein in the powder which makes them unable to be broken down and absorbed by the calf. Furthermore, the denaturing of protein causes the fat and protein bonds to break. This, in turn, allows the fat droplets to join together and become hydrophobic. This is why, when mixed at too high of a temperature, milk replacer can leave a greasy film on mixing and feeding equipment. In addition, denatured proteins tend to stick together. This can result in clumps in the milk replacer. If either of these were to occur, calves would not be able to breakdown and absorb the nutrients. This is why it is vital to follow the instructions on the feed tag. Esmilco milk replacers are formulated to ensure a uniform solution that is easy for the calf to digest, if it is prepared properly.

Feeding Temperature: Delivering Optimal Nourishment

Beyond mixing, it is just as vital to deliver milk to calves at a proper temperature. We recommend feeding milk replacers at 102-105°F. A calf’s body temperature is 102°F. If milk replacer is fed below the calf’s body temperature, then the esophageal groove does not completely close. The esophageal groove is what bypasses the reticulorumen and deposits the milk directly into the abomasum. When full closure of the esophageal groove does not occur, milk is allowed to enter the rumen. During the first couple months of life, the rumen is immature and unable to fully breakdown and absorb nutrients. This causes the milk to sit in the rumen and turn rancid, which leads to digestive upset; causing calves to go off feed which limits their growth and decreases their health.

Temperature Extremes: Pitfalls to Avoid

Feeding milk replacer at temperatures that are too cool or too hot can have adverse effects.

Issues with Feeding Milk Replacer- Too Cool Temperatures:

– Calves must expend energy to warm the milk to body temperature.

– Reduced feed efficiency, which can be a big problem during colder months.

– Milk can enter the rumen, causing digestive upset

– Fat does not melt into the solution

Issues with Feeding Milk Replacer- Too Hot Temperatures (>108°F):

– Too hot of a temperature may discourage calf consumption, negatively impacting health and performance.

– Denatures protein, causing them to be unable to be broken down and absorbed by the calf

Consistency and Monitoring for Success

Consistency is key in both mixing and feeding temperatures. Establishing a standard operating procedure (SOP) ensures that ideal temperature ranges are consistently maintained throughout the calf feeding process. Adapting procedures based on seasonal changes prevent milk from cooling excessively between mixing and feeding. For larger-scale operations, like calf ranches and large dairies, it’s crucial to take the temperature at the start of feeding the first calf, as well as at the end when feeding the last calf, to ensure both the beginning calves, and the calves at the end are getting milk replacer within the appropriate range.

In summary, mastering the art of milk replacer temperature control is a fundamental aspect of calf rearing. By understanding the nuances of mixing and feeding temperatures, you pave the way for optimal calf health, growth, and performance.